Campus networks and edge clouds offer new technological possibilities for Factory 4.0. This year, we will once again team up with our colleagues at

If you’re accepted into the program, you’ll have the opportunity to test your solution as a joint prototype in a demonstration center for campus networks in Germany, with which Deutsche Telekom cooperates. This means the teams will have the chance to demonstrate and test their solutions for Deutsche Telekom’s partners and customers.

Another special bonus for the teams is the possibility of being added to the

This year’s Campus Network Program focuses on computer vision and the specific related use cases. Interested startups can apply on the hubraum website until March 31.

I’ll be rooting for you and am looking forward to receiving your exciting applications!

A total success: The first Campus Network Program

In August, I explored the question as to how campus networks will transform the industryg With five startups from Europe and Israel, we and our colleagues at

The results were set up as a proof of concept (PoC) at the Center Connected Industry (CCI) on the campus of the technical university RWTH Aachen, where they were integrated directly in the campus network with 5G. As such, all PoCs are designed especially for Deutsche Telekom’s 5G campus networks and demonstrate potential uses for this network technology within the Industry 4.0 framework.

The following prototypes were developed:

- “That doesn’t sound good.” – Identifying the status of a machine by its noises

The Czech team at Neuron Soundware created a new way to optimize machine diagnostics and predictive maintenance. Their powerful artificial intelligence analyzes sound patterns from machines in real time, identifies deviations caused by wear and tear or malfunctions (anomaly analysis), and warns about mechanical failures at an early stage. This solution was linked with an augmented reality PoC fromT-Systems : A dashboard appears in the field of vision of smart glasses (Hololens) that contains an anomaly index value, among other information, so employees can see information about a machine’s status literally “in passing”. - “Is the delivery complete?” – Camera automatically checks number and correctness

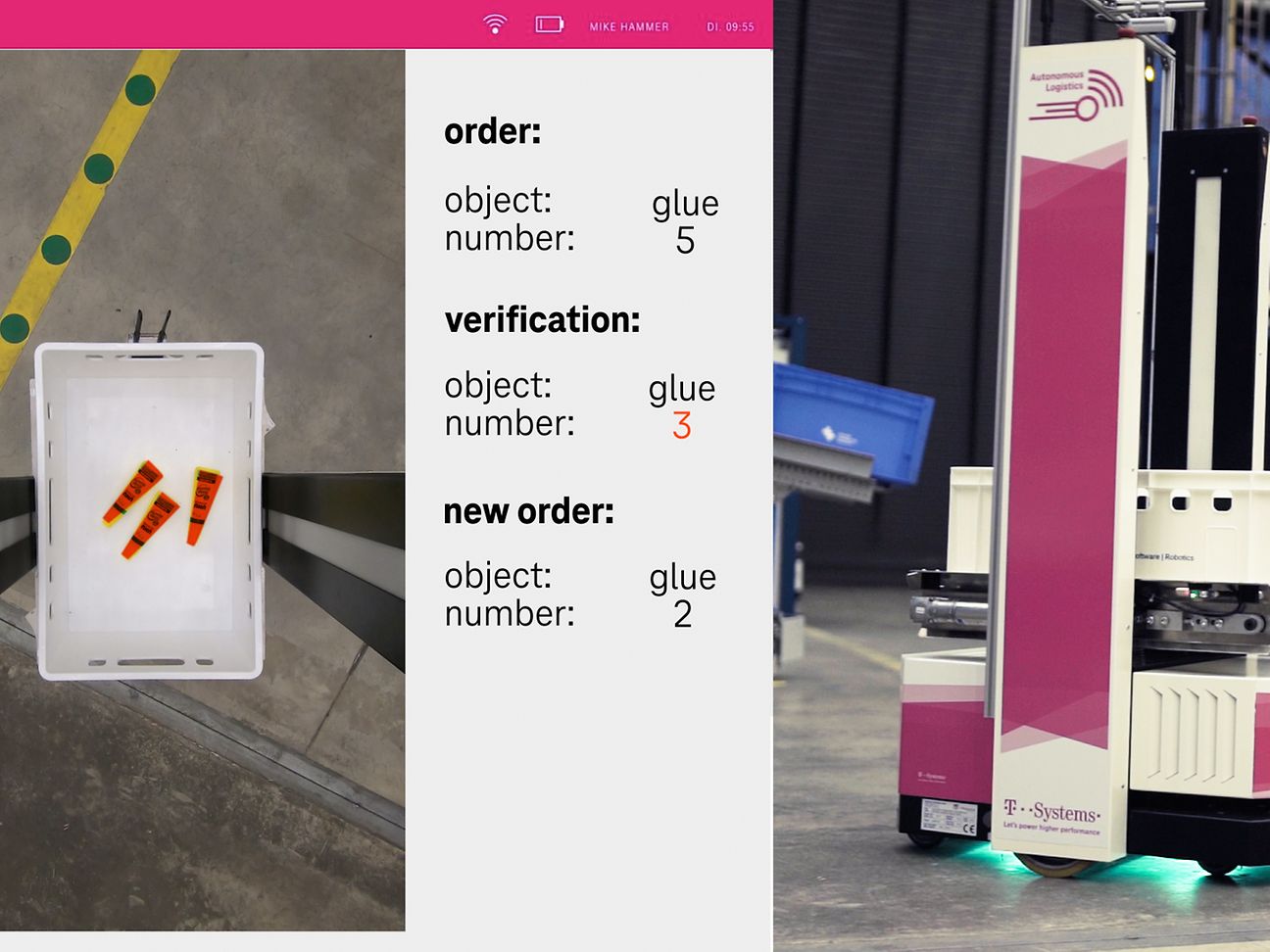

The Israeli startup RobotAI has linked computer vision (object recognition) with the possibilities of AGVs (automated guided vehicles).

The startup’s software uses artificial intelligence to perform automatic checks of picked articles (for the number and correctness of the articles). This is done during the transportation of the goods to the assembly point by the AGV. If a deviation is detected, a correction order is triggered automatically. - “Where is the article?” – Position data delivers exact location

The solution by the German startup Box ID involves the location determination of assets in the supply chain. In the PoC withT-Systems , the map and reporting functions are used for a campus position determination solution, which enables exact tracking and assessment of production goods on the company grounds. - “Smart glasses do their computations in the cloud!” – Making AR glasses even more convenient

The German startup Holo-Light is specialized in industrial AR applications for engineering and design. Their AR platform enables teams to work on complex 3D objects on a variety of output media. Their PoC demonstrates how the rendering of complex 3D content can be shifted to the edge cloud, which means the computing power no longer has to reside in the smart glasses. Only this combination of 5G and remote rendering makes it possible to display and model complex 3D components on AR glasses. - “Which way should I go?” – Virtual twin calculates optimized routes

The Austrian startup Incubed IT produces simulation software that optimizes the transportation routes of AGVs in a virtual twin of the real factory. The PoC demonstrates how the interaction between virtual and real AGVs works in a shop floor. This makes it possible to plan the expansion of an AGV fleet more effectively.

Our partner

I wish the teams continued success and look forward to winning new partners to our program.

Axel Menneking